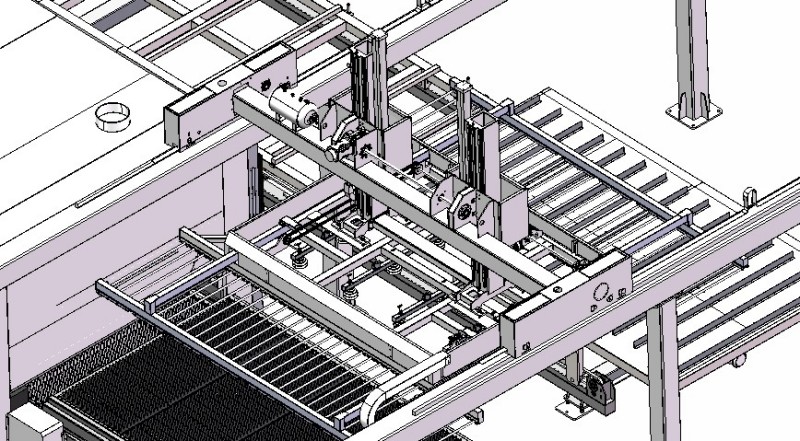

4020 Impande zombi zipakurura no gupakurura ukuboko kwa robo

Kwerekana ibicuruzwa

Ibikoresho bya tekiniki

| Ingano ntarengwa yo gupakurura no gupakurura | 4000 * 2000 | mm |

| Ingano ntarengwa yo gupakurura no gupakurura ingano ya plaque | 1500 * 1000 | mm |

| Umubare ntarengwa wo gupakurura no gupakurura uburebure bwa plaque | 50 | mm |

| Ntarengwa gupakira no gupakurura uburebure bwa plaque | 0.8 | mm |

| Uburemere ntarengwa bwo gupakira no gupakurura | 3000 | kg |

| Uburemere bumwe bwo gupakira uburemere bwimodoka | 6 | T |

| Uburebure bumwe bwo gupakira uburebure bwimodoka | 200 | mm |

| Ubukanishi bwamaboko yihuta | 10-30 | m / min |

| Umuvuduko wo kuzamura amaboko | 5-10 | m / min |

| Umuvuduko wibikoresho byamashanyarazi umuvuduko | 10 | m / min |

| Imbaraga z'ibikoresho | 10 | Kw |

| Ibikoresho byo gufata umwuka | 12 | mm |

| Ibikoresho byo mu kirere | 0.6-0.7 | Mpa |

| Ibisabwa Imbaraga | 3-icyiciro 5-wire 380V |

|

Imashini

Ibikoresho by'ingenzi bigize ibice bigize urutonde

| Inomero y'uruhererekane | Izina | Ikirango | Ongera wibuke |

| 1 | Kuzamura umurongo uyobora | Tayiwani HIWIN cyangwa Ubuyapani SMG |

|

| 2 | Kuzamura umurongo | Tayiwani HIWIN cyangwa Ubuyapani SMG |

|

| 3 | Gukoraho ecran ya mashini yumuntu | Shanghai Flexem |

|

| 4 | Umugenzuzi wa Vacuum | Tayiwani KITA cyangwa SNS |

|

| 5 | Ubuyobozi buyobora umurongo | Tayiwani HIWIN cyangwa Ubuyapani SMG |

|

| 6 | Sobanura umurongo ugaragara | Tayiwani HIWIN cyangwa Ubuyapani SMG |

|

| 7 | Umugenzuzi wa CNC | Ubuyapani OMRON |

|

| 8 | DC Amashanyarazi | Ubuyapani OMRON |

|

| 9 | Ikiruhuko | Ubuyapani OMRON |

|

| 10 | Igikombe | REZES |

|

| 11 | Ibigize umusonga | Tayiwani AIRTAC cyangwa SNS |

|

| 12 | Motor Motor | Raynen | Ubwoko bunini bwa inertia |

| 13 | Kugabanya neza | Shanghai YINTONG cyangwa Hangzhou KAXIELI | Iminota 8 arc |

| 14 | Kuzunguruka | C&U | Kubungabunga |

| 15 | Ibyuma bifata amashanyarazi | CHIIB | Urukurikirane rwa CHIIB |

| 16 | Kumena | Schneider | Delixi |

4020 Impande zombi za gantry zipakurura no gupakurura amaboko ya robot Igisubizo cya tekiniki

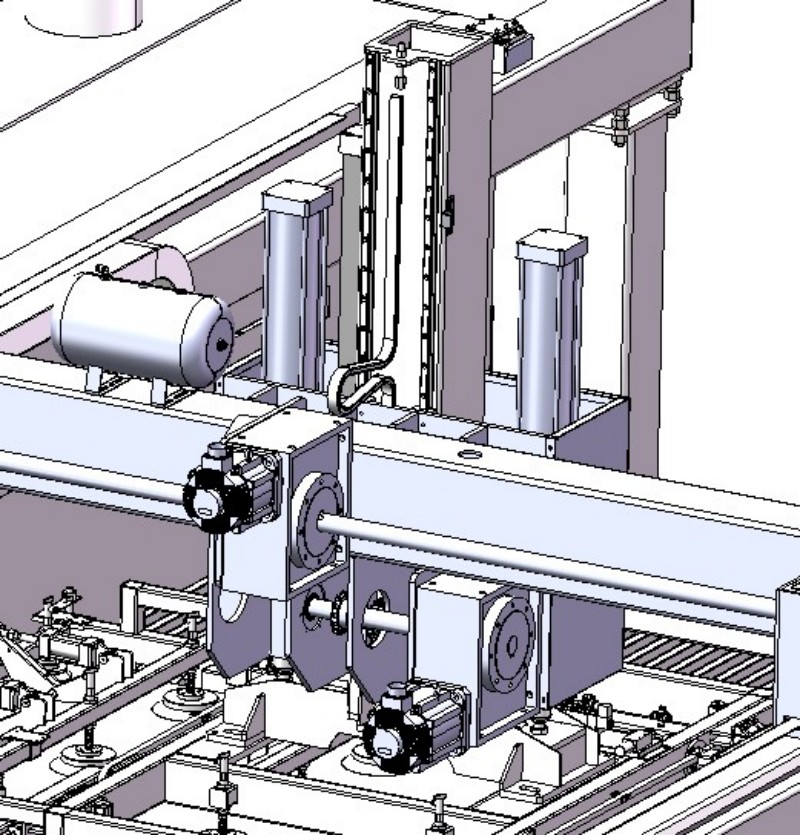

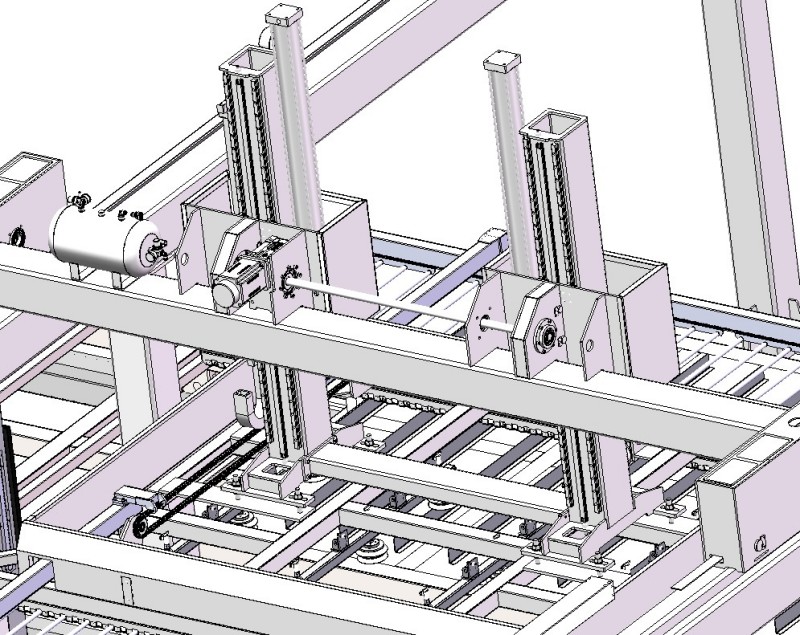

1.Mipulator itwarwa na moteri ya servo ikoresheje kugabanya neza, hamwe na stroke yo guterura yose hamwe ya 700mm hamwe nurugendo rwa 4500mm (byahinduwe ukurikije uko ibintu bimeze)

2.Ibice byinshi byamavuta ya vacuum yihanganira ibikombe byokunywa, buri gikombe cyokunywa gifite ibikoresho byintoki, bishobora gufungwa nintoki kandi bigahinduka ukurikije ubunini bwisahani. Gusubiramo umwanya wukuri wa robot igaburira ni ± 2mm.

3.Imperuka ifite ibikoresho byo gutandukanya isahani ya pneumatike kugirango byorohereze gutandukanya amasahani mugihe cyo kugaburira byikora. Icyitonderwa: Bitewe nimbaraga zinyuranye za adsorption hamwe nibirimo amavuta hagati yamasahani, ntabwo byemezwa ko amasahani ashobora gutandukana burundu neza. Gutandukana kwabantu bifashwa birashobora gukorwa ukurikije ibihe bifatika.

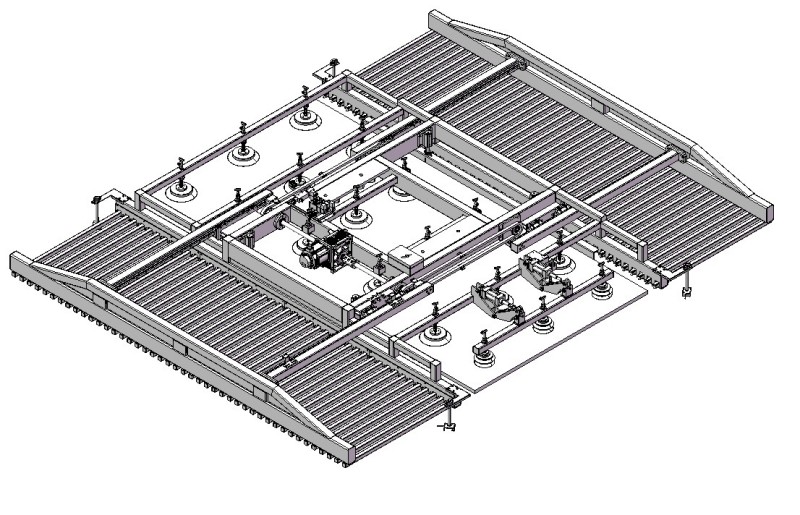

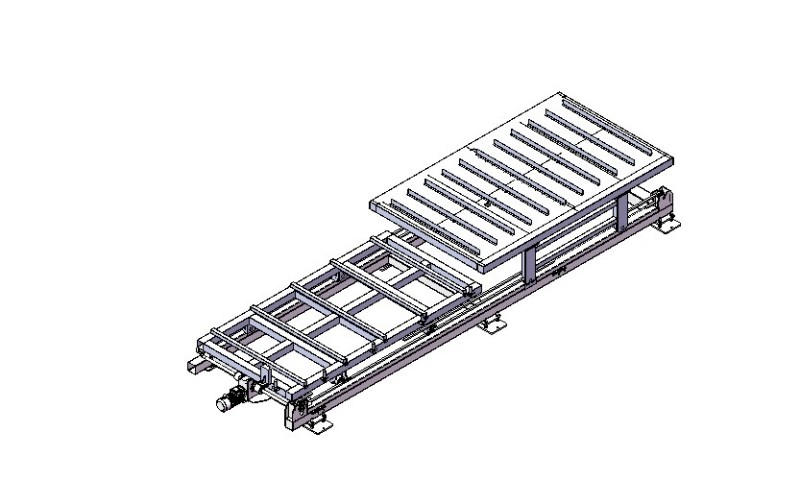

4.Ibikoresho byo gupakira no gupakurura byashyizwemo igare 1 ryibikoresho bibiri byamashanyarazi (igorofa yo hejuru) kugirango imashini ya laser ibike ikariso yimashini yuzuye yarangije gukata, hamwe nigare 1 ryamashanyarazi (layer yo hepfo) kugirango imashini ya laser itange ibikoresho bibisi.

5.Ikamyo yibikoresho itwarwa na moteri yihuta kandi ifite ibikoresho bya feri ya electronique. Bifite ibikoresho byimukanwa bitandukanya ibintu, biroroshye kwamamaza adsboard ikibaho cyo kugabana no kunoza igipimo cyo gutsinda cyo gutandukana.

6.Gupakurura bifata ibyuma bibiri-bipakurura manipulator hamwe nigikombe cyo gupakira cyahujwe nuburyo bumwe bwo guterura inkingi. Uburyo bwo gupakurura nuburyo bwibumoso nuburyo bwiburyo bubiri, ikibanza cyo gupakurura gifite intera ngufi yo kwiruka nigipimo gito cyo gutsindwa.

7.Ibikoresho bikoreshwa na servo yuzuye. Kuzamura no kuruhande rwa manipulator byose bitwarwa na moteri ikomeye ya servo. Sisitemu yo guterura imashini ifite umurongo uyobora umurongo, hamwe n'umuvuduko wihuta kandi uhagaze neza.

8.Ubugenzuzi bukoresha ecran ya ecran 10 yatumijwe hanze hamwe na sisitemu ya CNC ifite ubwenge ya progaramu ya Omron. Ifite uburyo bwikora nuburyo bwintoki. Igenamiterere ryose, kugenzura, no gukemura birashobora gukoreshwa n'intoki kuri ecran, byihuse kandi byoroshye.

9.Ibidukikije bikora byiyi mashini bigomba kuba byujuje ibisabwa -10-45 ℃ ubushyuhe, ubuhehere bugereranije buri munsi ya 80%, nta bikoresho byaka kandi biturika, kwivanga gukomeye kwa electronique, nta gaze yangirika, nta kumeneka kwamazi, no kumurika neza murugo.

Imikoreshereze Intangiriro

1.Umukoresha arashobora guhinduranya hagati yuburyo bwo gupakira bwikora nuburyo bwo gupakira intoki ukoresheje ecran yo gukoraho kugirango ihuze nibikorwa bitandukanye.

2.Uburyo bwo kwipakurura: Koresha igice cyo gutandukanya ibikoresho byo hasi kugirango ufungure, kandi igikombe cyimbere cya vacuum imbere gikurura isahani. Igikoresho cyo guterura kiraterurwa kandi kigenda gitambitse kuri mashini ya laser kugirango ushyire isahani kumurongo wa laser.

3.Uburyo bwo gupakurura ibikoresho bifata amashanyarazi ibumoso nuburyo bwiburyo bubiri. Ikibanza cyo gupakurura gifite intera ngufi yo kwiruka nigipimo gito cyo gutsindwa. Gufungura no gufunga ikariso ikoresha amenyo ya kwadarato yinyo yinyo, ifite ubushobozi bunini bwo kwikorera imitwaro hamwe nubushobozi bukomeye bwo kurwanya deformasiyo. Ahantu ho guhurira hagati yikibaho nisahani ni nto kandi ntigushushanya isahani. Ikibanza cya kabiri gifungura kandi gifunga icyarimwe mubyerekezo byombi kumurongo wa gari ya moshi uyobora kandi utwarwa na moteri ya feri ya electronique.

4.Umubiri wa manipulator wo gupakira no gupakurura bikozwe mu miyoboro yicyuma cya manganese hamwe nicyuma cyiza cyo mu rwego rwo hejuru, gisudira muri rusange hanyuma kigavurwa no kugabanya umuvuduko ukabije, kandi bigatunganywa n’imashini nini yo gusya ya CNC. Ifite ubukana bwiza kandi busobanutse neza. Igiti cya gantry n'amaguru bihujwe no guhindura ibihindu, bikaba byoroshye muguhindura utambike twibiti bya gantry. Gukoresha no gupakurura manipulatrice itwarwa na moteri ya servo ikoresheje kugabanya neza kandi ifite ibikoresho byoherejwe kumurongo. Uburyo bwo guterura bufite ibikoresho bingana na silinderi iringaniza kugirango iteze imbere guterura umuvuduko mwinshi kandi wirinde ibibazo byinyeganyeza mugihe cyimikorere yuburyo bwo guterura.

Igishushanyo Cyiza Igishushanyo

Ibikoresho byo gutegura ibikoresho

1. Tegura amashanyarazi 380V60A hamwe na 5-core 10mm² y'amashanyarazi kugirango uhuze igikoresho.

2.Isoko ryumuyaga uhumanye hamwe numuvuduko wakazi wa 0.6MPa numuyoboro wumuyaga uhujwe nibikoresho.

3. Shiraho ibimenyetso byo kuburira umutekano hamwe nuburyo bukoreshwa mubikoresho bikoreramo.

Kwirinda umutekano

1.Abakora birabujijwe kwinjira mu gice cy’ibikoresho bigendanwa mu rwego rwakazi ;

2.Abantu binjira mu kazi basabwa guhugura umutekano ;

3. Mbere yo gukoresha robot, ugomba kwemeza niba imikorere ikora yujujwe.

Serivisi

--- Serivisi ibanziriza kugurisha:

Ubuntu Mbere yo kugurisha Ubujyanama / Icyitegererezo cyubusa

REZES Laser itanga amasaha 12 byihuse mbere yo kugurisha no kugisha inama kubuntu, Ubwoko bwose bwa tekiniki ni

kuboneka kubakoresha.

Gukora Icyitegererezo Cyubusa birahari.

Kwipimisha Icyitegererezo kubuntu birahari.

Dutanga igisubizo gitera imbere kubagabuzi bose hamwe nabakoresha.

--- Serivisi nyuma yo kugurisha:

1.3 garanti yimashini ikata fibre laser

2.Inkunga yuzuye ya tekiniki \ ukoresheje imeri, guhamagara na videwo

3.Ibihe byose byo kubungabunga no gutanga ibikoresho.

4. Igishushanyo cyubusa cyibikoresho nkuko abakiriya babisabwa.

5. Kwishyiriraho ubuntu kubuntu no gukora kubakozi.

Ibibazo

1. Ikibazo: Kuki tugomba kuguhitamo?

Igisubizo: niba uduhisemo, uzabona ubuziranenge, serivise nziza, igiciro cyiza na garanti yizewe.

2.Q: ntabwo nzi imashini, nahitamo ute?

Igisubizo: Gusa tubwire ibikoresho, ubunini nubunini bwakazi, l izasaba imashini ibereye.

3. Nigute ushobora gukoresha imashini?

Igisubizo: Tuzabagezaho igitabo cyicyongereza na videwo hamwe na mashini kuri wowe.niba ukeneye ubundi bufasha bwacu, twandikire.

4.Q: Urashobora kubona icyitegererezo cyo kugenzura ubuziranenge bwimashini?

Igisubizo: Birumvikana. Nyamuneka uduhe ikirango cyawe cyangwa igishushanyo kuri twe, ingero z'ubuntu zirashobora kuguha.

5.Q: Imashini irashobora gutegurwa nkurikije ibyo nsabwa?

Igisubizo: Nibyo, dufite itsinda rya tekinike rikomeye kandi dufite uburambe bukomeye. Intego yacu nukugushimisha.

6.Q: Urashobora kudutegurira ibyoherejwe?

Igisubizo: Birumvikana. Turashobora gutegura ibyoherejwe kubakiriya bacu dukurikije inyanja nikirere. Amagambo yo gucuruza FOB, ClF, CFR arahari.